Stay Compliant. Stay Safe.

Simplified crane safety standards for operators and contractors

Explained clearly for operators, managers, and safety officers.

What Are Crane Safety Standards—and Why Are They Important?

Crane safety standards are official regulations and best practices designed to prevent accidents, improve operational safety, and ensure compliance on job sites using lifting equipment. These standards are created by key organizations like ASME, OSHA, ANSI, and NCCCO, and they apply to everything from crane inspections and load handling to operator certification and rigging procedures.

Meeting crane safety standards isn’t just about avoiding fines—it’s about protecting your workers, equipment, and business. By following OSHA crane regulations, ASME B30 safety codes, and NCCCO certification requirements, companies can:

-

Reduce the risk of crane accidents and equipment failure

-

Stay compliant with federal and state crane safety laws

-

Ensure operators and riggers are properly trained and certified

-

Improve job site efficiency and lower liability

Whether you’re managing mobile cranes, tower cranes, or rigging operations, understanding these safety standards is essential. Crane Safe LLC makes it easy to meet and maintain compliance with expert training, inspections, and consulting services based on today’s most trusted crane safety regulations.

ASME B30 Safety Codes

The American Society of Mechanical Engineers (ASME) sets industry-accepted technical safety standards like B30.5 for mobile cranes and B30.3 for tower cranes. These standards guide the safest crane operation practices in the field today.

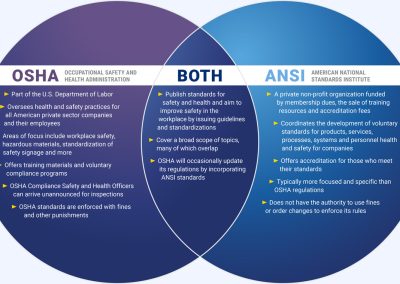

OSHA Regulations

OSHA enforces crane safety laws in the workplace, including operator certification, inspections, and hazard prevention. Noncompliance means fines or worse—accidents.

ANSI Guidelines

ANSI works with ASME to establish crane equipment standards that manufacturers and workplaces use. We break down what ANSI standards mean for your safety gear and operations.

NCCCO Certification

To operate cranes legally and safely, many jobsites require NCCCO-certified operators. We train, test, and certify according to the most respected program in the U.S.

Key OSHA Requirements

Operator Certification

All crane operators must be certified through an accredited program such as the NCCCO to meet OSHA standards (29 CFR 1926.1427). Certification involves passing written and practical exams specific to the type of crane operated. Employers are responsible for ensuring each operator’s credentials are current and applicable to the task.

Why it matters: Certified operators reduce risk, avoid fines, and demonstrate proven competence on the job.

Inspection Frequency

OSHA mandates routine crane inspections based on usage:

- Daily/Pre-shift inspections (visual checks by operator)

- Monthly documented inspections (performed by competent personnel)

- Annual inspections (comprehensive review by a qualified inspector)

Compliance Tip: Missing documentation or improper inspection intervals can lead to citations or jobsite shutdowns.

Lift Planning Requirements

OSHA requires that all critical lifts or non-routine operations be supported by a detailed lift plan. This includes:

- Load weight & center of gravity

- Equipment selection

- Ground condition assessment

- Communication protocols

Why it matters: Proper planning minimizes surprises and keeps your team aligned and safe.

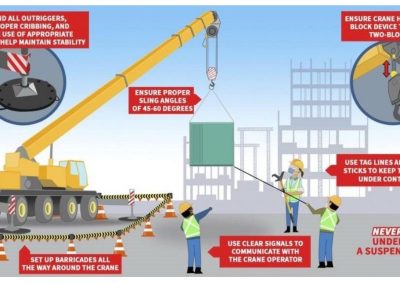

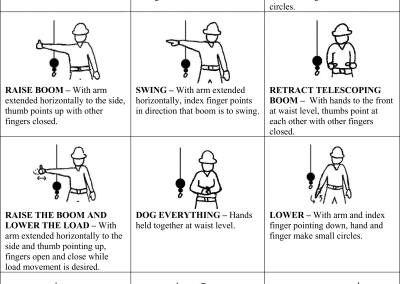

Signal/Rigger Requirements

Signal persons must be qualified by either a third-party evaluator or through an employer’s qualification process per OSHA 1926.1428. Riggers must be qualified for the type of rigging work performed when handling loads.

Key Point: Inadequate communication or rigging skills are a leading cause of crane-related incidents.

Load & Site Guidelines

Before any lift, OSHA requires evaluation of load weight, radius, and configuration, along with site-specific conditions such as overhead power lines, weather, and ground stability. Cranes must not operate near energized power lines without proper clearance.

Safety Reminder: Ignoring site hazards or overloading equipment can result in catastrophic failure.

Common Violations & Prevention

Fall Protection

Falls are the leading cause of injuries and fatalities in the construction industry. Elements that impact fall frequency include poor structural integrity, damp surfaces, and unsuitable footwear. All employees reaching heights that are six feet or higher must receive proper fall protection training.

Inspections

All crane personnel should know how to properly inspect equipment before using it. Routine inspections are necessary to ensure proper function and safety throughout the job. Operators should follow all equipment inspection instructions that are outlined in the owner’s manual.

Signal Person Qualifications

Construction sites are noisy. Since it can be difficult to hear verbal instructions, having someone dedicated to providing hand signals to the crane operator is essential. The signal person and the operator should implement proper hand, radio, and special signals anytime cranes and other heavy equipment are being used. These signals keep everyone on the same page. OSHA requires the signal person to exhibit competency through an oral or written exam along with a practical exam.

Power Line Safety

Operators must know and maintain the minimum approach distance at all times. This simply means how close a crane can get to power lines before they become hazardous.

Keeping Clear of the Load

Only certain crew members can be in the fall zone during an operation, and no crew members should ever stand directly below the load.

Assembly/Disassembly

Only qualified personnel should be in charge of assembling and disassembling any type of crane.

Operator Qualification & Certification

All crane operators must be trained, certified, and evaluated by an accredited and nationally recognized entity before operating a crane on the job site. Unqualified operators can put not only themselves but everyone else in danger.

Lockout/Tagout

Lockout or tagout refers to hazardous energy control during maintenance checks that protect workers from amputations and other serious injuries resulting from sudden machine startup and stored energy release. Common injuries that result from a lack of lockout or tagout include:

- Electrocution

- Burns

- Crushing

- Cuts

- Lacerations

- Amputations

- Fractures

Respiratory Protection

When the permissible exposure limit (PELs) of airborne contaminants is relatively high, employers must provide employees with proper personal protective equipment (PPE), like masks and respirators. This PPE prevents workers from developing respiratory problems due to workplace contaminants.